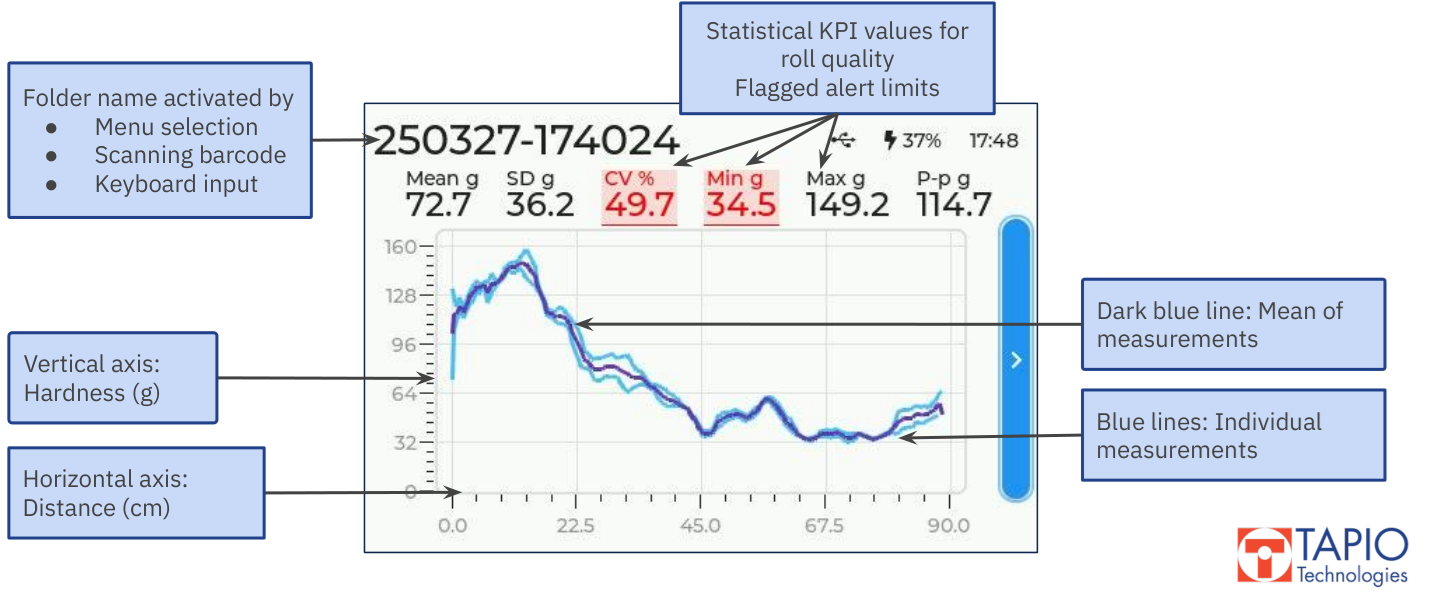

Reducing plastic film roll rejections with roll hardness profiling

Reducing plastic film roll rejections with roll hardness profiling The Tapio RQP Live produces an instant high-resolution hardness profile. Alert limits for out-of-spec rolls allow for immediate flagging of problematic