Locate problematic machine elements using Tapio MD Analysis

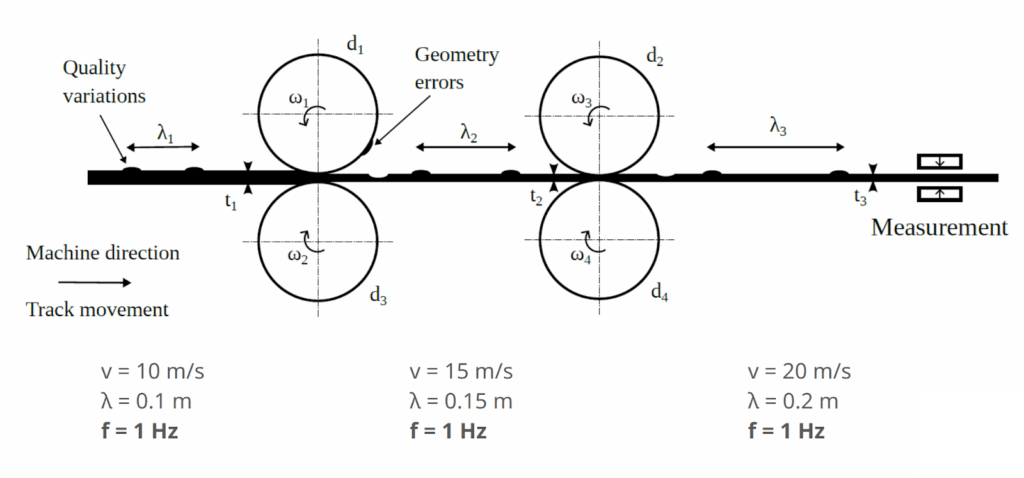

Locate problematic machine elements using Tapio MD Analysis In paper, board, and other continuous production processes where the product is formed by rolling or pressing, every rotation of any mechanical element affecting the web — such as a roll, felt, wire, or pump — leaves a repeating pattern related to quality variation on the final […]

Hidden defects in rolls: a closer look with Tapio RQP Live

Hidden defects in rolls: a closer look with Tapio RQP Live A paper, board or plastic roll may appear perfectly fine on the outside. The surface layers may seem to be uniform, smooth, and free of any obvious defects. However, beneath the outer layers, hidden issues can exist that compromise the performance and quality of […]

Hidden roll defects are costing you more than you think

Every mill knows the frustration of a “bad” roll — unscheduled downtime, customer complaints, wasted materials, and production delays. But what if you could detect roll defects before they cause expensive problems? The good news: you can. And it starts with understanding roll hardness profiles.