A plastic film producer was experiencing quality issues: around 25% of produced rolls were rejected by the customer in converting. Visual inspection and process data did not explain the problem, as the rolls looked normal at the production site.

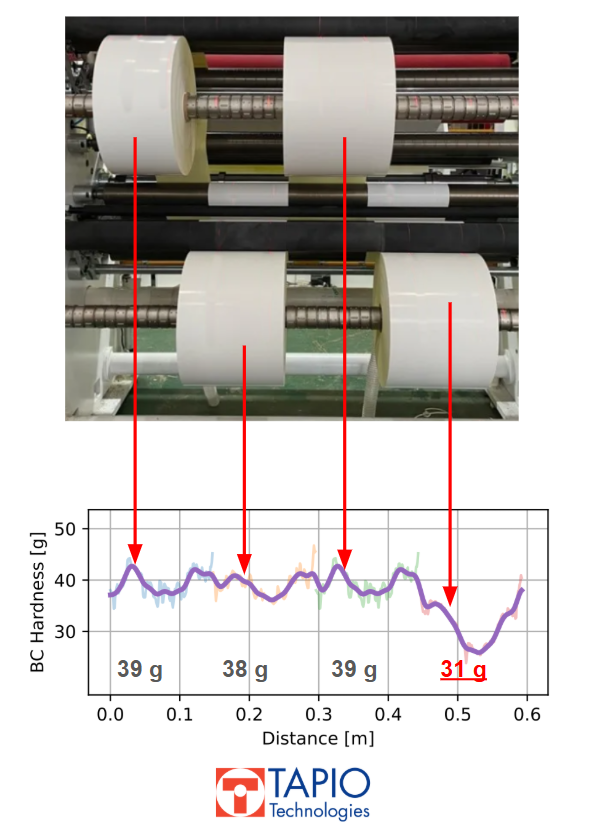

The producer started measuring roll hardness with the Tapio RQP Live directly at the rewinder. Each roll was measured separately, and the results were then combined using Tapio RollView continuous mode, which allows single roll measurements to be viewed as one continuous hardness profile.

The hardness profiles showed that the edge rolls were softer than the others. One roll had a hardness of about 31 g, while the remaining rolls were in the range of 38–39 g. This corresponded well with the rolls that later caused converting issues. Such differences may be caused by misalignment, tension differences or variations in the cross-direction thickness profile.

Without hardness measurements, this difference in the rolls would not have been visible. Furthermore, only the middle part of the edge roll was softer while the edges of this roll were of similar hardness to the other rolls. This is a situation that may not have been revealed by single-point hardness testers. Tapio RQP Live measures hardness 30 times per second simultaneously with distance, producing a high-resolution hardness profile.

Tapio RQP Live provides insight into winding quality across the full web width for paper, board, and plastic films as well as other rolled products. Unlike many other quality control systems, the hardness profile data is obtained easily and non-destructively from real rolls after production, storage and transport. RQP Live helps producers move beyond single-point measurements and subjective assessment, to ensure consistent quality and prevent costly roll defects.