In modern paper production, achieving an efficient and accurate cross-direction (CD) profile is critical for product quality and production cost control. In typical production lines, online scanners provide the operators with the CD profile. However, online QCS (Quality Control System) scanners have inherent limitations: they are restricted by resolution and always contain some degree of machine direction (MD) variation, making it challenging to obtain a true, undistorted CD profile.

High-resolution Tapio CD profile measurements overcome these limitations. Tapio measurements provide true CD profiles from actual CD strips without any MD distortion. Using sub-millimeter sample spacing with small sensor apertures, each sensor measures the exact same point in paper, allowing for detailed correlation studies as well as the investigation of formation-level phenomena. In addition, Tapio profiles extend all the way to the very edges of the produced paper sheet, a region where QCS scanners often have limited visibility.

With Tapio Analysis, mills can easily optimize CD profiles by identifying inefficiencies and localized profile defects. The accurate measurements can also be used for tuning and calibration of QCS scanners, ensuring better scanner alignment, actuator response, and overall process stability.

Figure: Tapio Measurement Technologies provides high-resolution CD measurement services from customer-supplied CD strips. Typically, 30 full-width strips from the parent reel are needed for a complete analysis. At Tapio’s laboratory, the strips are carefully prepared into a sample roll, enabling full high-resolution scanning with a Tapio Analyzer. Results are provided as a report with an online meeting with Tapio experts to discuss the results.

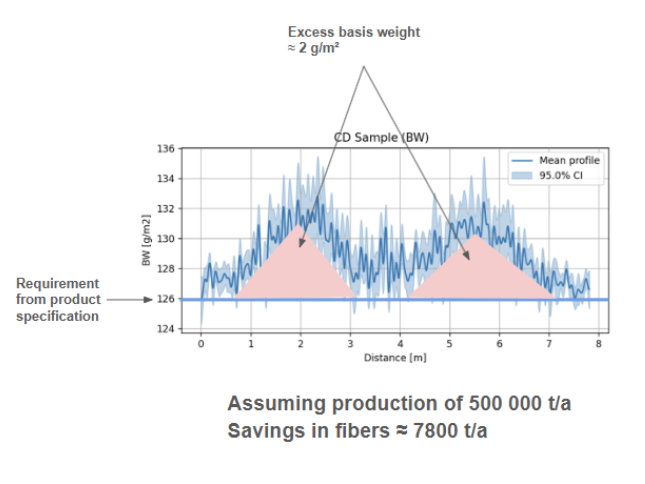

Figure: Excess grams in basis weight profiles accumulate into large amounts of unnecessary fiber costs. In this example, small but persistent excesses in basis weight across the CD direction result in significant material overuse. Even a few grams per square meter, when scaled to full production volumes, can lead to substantial unnecessary fiber costs. High-resolution Tapio profiles help mills detect and correct these inefficiencies, supporting better cost control and sustainability goals.

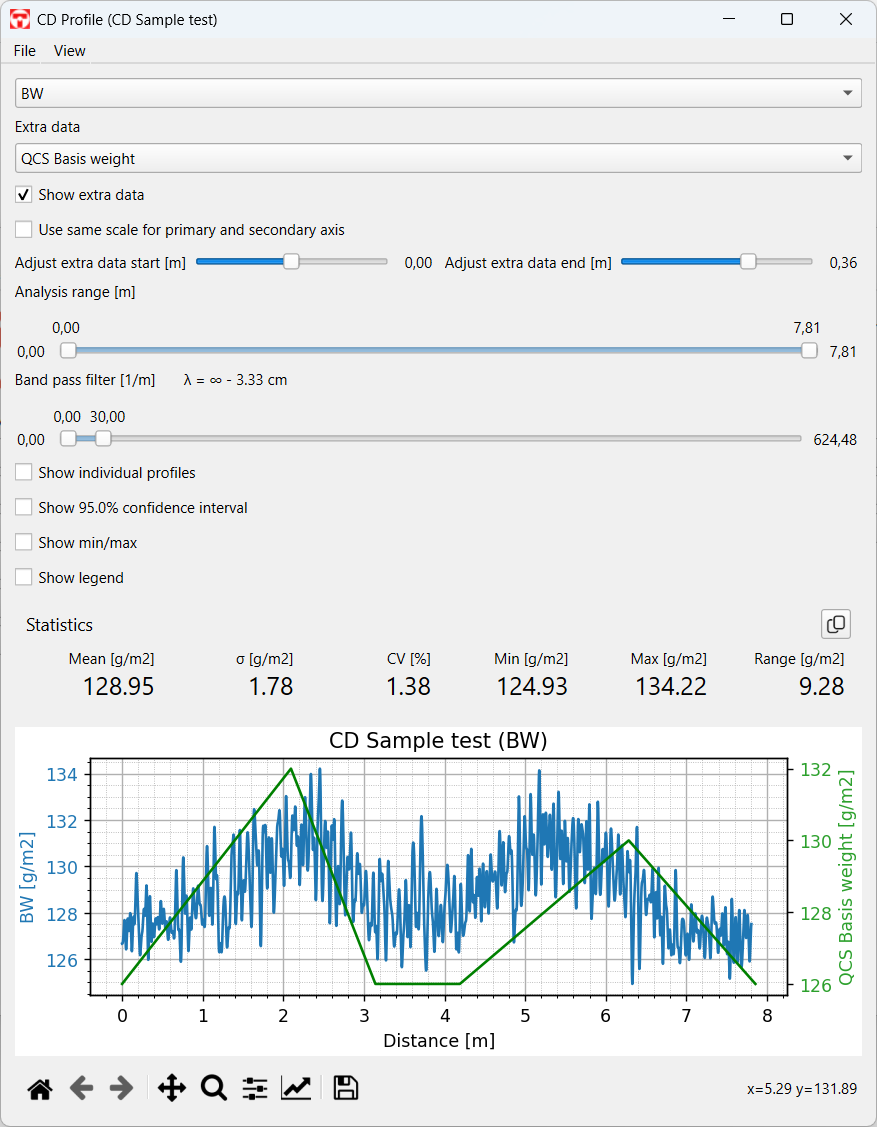

Figure: The open-source Tapio Analysis software (https://github.com/Tapio-Measurement-Technologies/tapio-analysis) allows the user to easily compare high-resolution Tapio CD profiles with provided QCS or other external data. Overlaying Tapio’s undistorted, high-resolution measurements with QCS data reveals discrepancies that may not be visible using online scanners alone.

What is needed

Please send us 30 full-width CD strips from a parent reel. The strips should be ~50 cm wide if hand-cut strips are used. We can accept strips from standard sample cutters as well.

Possibilities of Tapio CD Analysis