A winder–cutter is not an easy system to optimize. Changing web tensions, roll diameters, masses and rotational frequencies all interact, and the behaviour of the machine changes continuously during the winding cycle. This makes it challenging to avoid resonances and unwanted vibration.

During the past year, the Tapio analysis and troubleshooting team has been involved in several industrial vibration cases related to winding, working with the ARotor rotating machinery group at Aalto University. This article summarises the key findings so far.

High-resolution caliper (thickness) data obtained with the Tapio Analyzer

To study the source of paper and board variations, reliable high-resolution thickness data is essential. The Tapio Analyzer can provide this by measuring MD and CD samples under controlled conditions.

The instrument can measure several quality parameters non-destructively and each from the same spot in paper with a small aperture size. A typical setup consists of sensors for basis weight, caliper, dual-sided gloss, ash and transmission.

The MD samples used for vibration studies are often several kilometres long and data is obtained at millimeter-level sampling spacing with millimeter level apertures under controlled conditions. From these high-resolution profiles, a spatial spectrum can be calculated. The spectrum reveals how different frequencies, such as rotating components (rolls, felts, pumps, motors), appear in the paper. By some further analysis, it is possible to determine whether they might transfer into the winding process.

The Tapio Analyzer MD samples are usually several kilometers long, and a spatial spectrum of the variation can be calculated, yielding a result how different frequencies (these can be connected to rotating frequencies of rolls, felts, pumps etc.) occur in the paper samples.

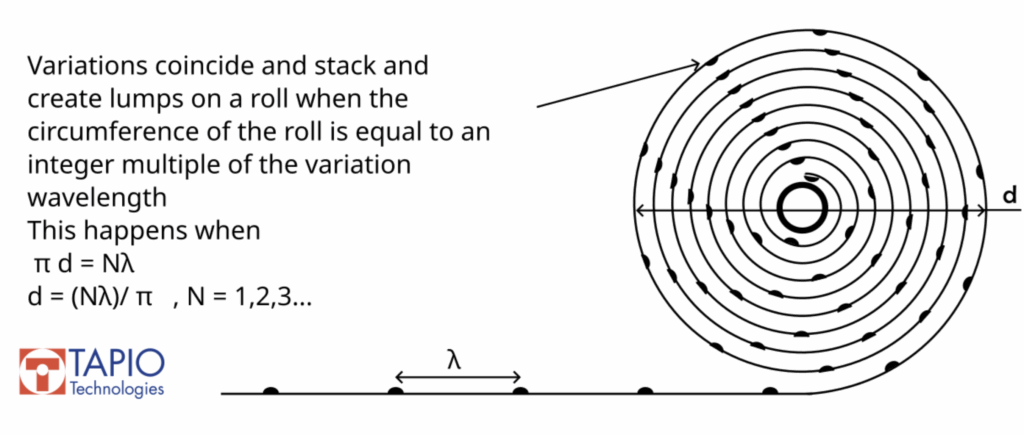

One of the main discoveries in our studies is that winder vibrations may be excited by variations in the wound product. Figure 2 shows a schematic on how periodic product variations will stack on top of each other every time the roll circumference is equal to the variation wavelength.

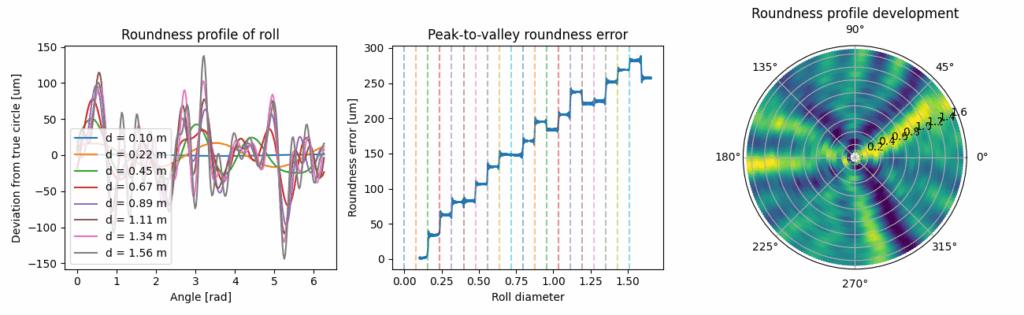

When the formed geometry errors actually excite vibrations may seem random, because the geometry errors or lumps are not formed in uniform angular intervals. Figure 3 presents a simulated case of how the roundness profile develops in a roll of with a caliper of 140 μm having with a small thickness variation of 1 micrometer peak-to-peak at a 25 cm wavelength. It can be seen how the micrometer-level roundness error stacks up and develops.

This effect can be especially significant in thin products, where even minimal but periodic thickness variations can create significant geometry errors. Furthermore, grades with a high coefficient of friction may be more susceptible to vibration problems because the roll geometry errors cannot “correct themselves”.

In a recently conducted master’s thesis at Aalto University (Seth Altobelli: Effect of paper thickness variation on paper roll roundness), a measurement setup was for studying the roll geometry error was created, consisting of simultaneous caliper measurement in a Tapio Analyzer with a multi-probe roundness measurement setup to simultaneously measure roll roundness error accurately. While still preliminary, the results show the potential for further research. Further studies are planned on measuring caliper variations as well as roll geometry variations simultaneously, as well as vibration measurements on winders. Research on the topic continues and results are expected within the following years.

In a recently conducted master’s thesis at Aalto University, a device consisting of simultaneous caliper measurement in a Tapio Analyzer. While still limited, the results show the potential for further research. Further studies are planned on measuring caliper variations as well as roll geometry variations simultaneously, as well as vibration measurements on winders. Research on the topic continues and results are expected within the following years.

If you suspect that your winder vibration issues are related to periodic variations in your product, Tapio Analysis can be used to identify the variation patterns and their wavelengths.

You can send us a roll of your product for analysis. More information about the service and sample requirements is available on our website: Tapio Analysis Services and Troubleshoting Consulting.