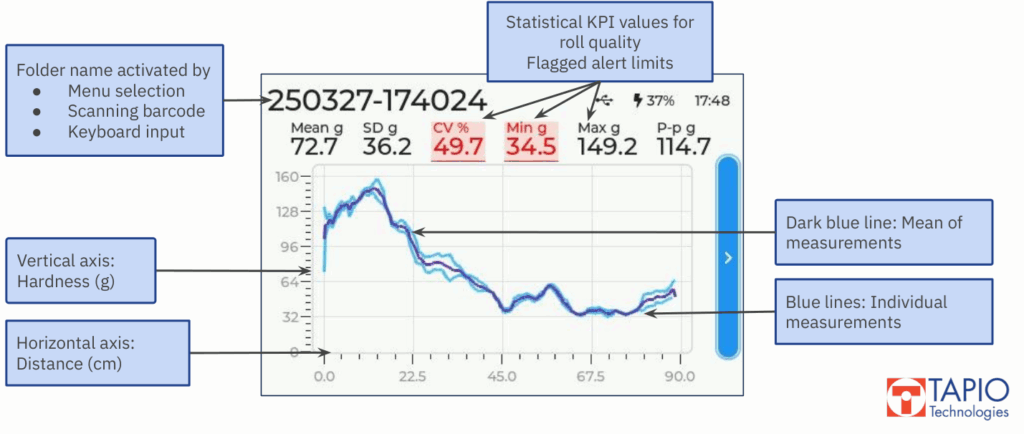

Reducing plastic film roll rejections with roll hardness profiling

Reducing plastic film roll rejections with roll hardness profiling The Tapio RQP Live produces an instant high-resolution hardness profile. Alert limits for out-of-spec rolls allow for immediate flagging of problematic rolls. A plastic film producer was experiencing quality issues: around 25% of produced rolls were rejected by the customer in converting. Visual inspection and process […]

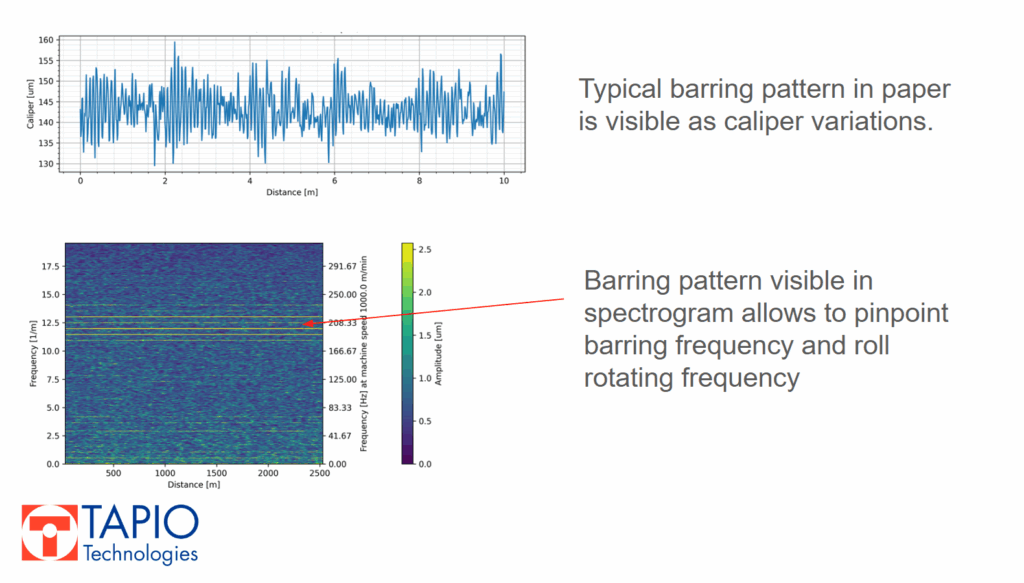

How Tapio Analysis Helps Solve Barring Problems

How Tapio Analysis Helps Solve Barring Problems In paper and board production, calender roll barring is a significant problem which can lead to unscheduled maintenance breaks and visible defects in the end product. Although the exact root cause of barring is not always immediately clear, it can originate from small thickness or basis-weight variations already […]

How Product Variations Can Cause Winder Vibration

How Product Variations can Cause Winder Vibration A winder–cutter is not an easy system to optimize. Changing web tensions, roll diameters, masses and rotational frequencies all interact, and the behaviour of the machine changes continuously during the winding cycle. This makes it challenging to avoid resonances and unwanted vibration. During the past year, the Tapio […]

Roll Hardness Profiles – What Can the Statistics Tell Us?

Roll Hardness Profiles – What Can the Statistics Tell Us? Quality of rolls is not about appearance – it depends both on the rolled material and on how the roll has been wound. The hardness profile provides valuable insight into roll condition and helps detect faults that are often invisible to the eye or missed […]

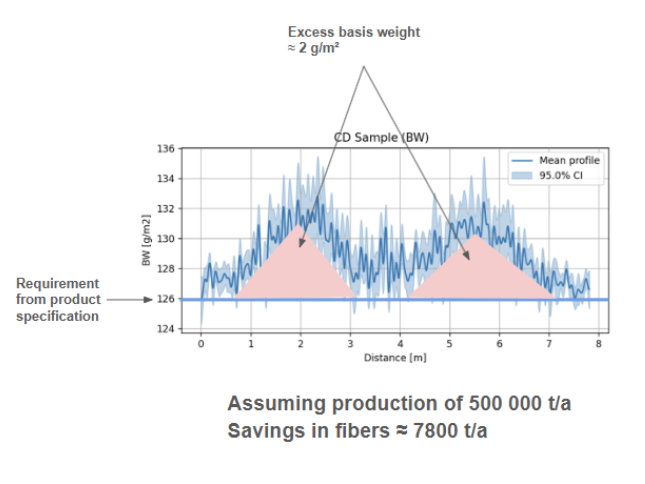

Optimizing paper and board machine CD profiles with Tapio Analysis

Optimizing paper and board machine CD profiles with Tapio Analysis In modern paper production, achieving an efficient and accurate cross-direction (CD) profile is critical for product quality and production cost control. In typical production lines, online scanners provide the operators with the CD profile. However, online QCS (Quality Control System) scanners have inherent limitations: they […]

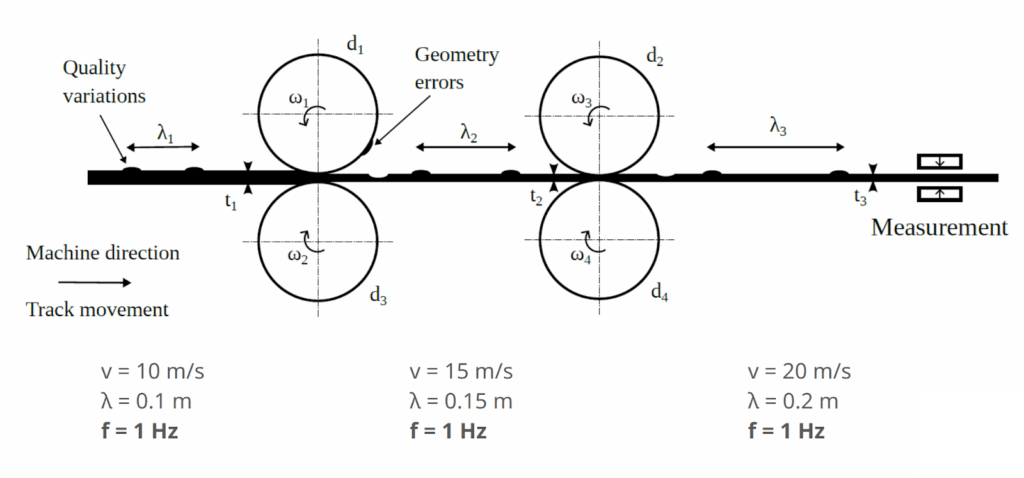

Locate problematic machine elements using Tapio MD Analysis

Locate problematic machine elements using Tapio MD Analysis In paper, board, and other continuous production processes where the product is formed by rolling or pressing, every rotation of any mechanical element affecting the web — such as a roll, felt, wire, or pump — leaves a repeating pattern related to quality variation on the final […]

Hidden defects in rolls: a closer look with Tapio RQP Live

Hidden defects in rolls: a closer look with Tapio RQP Live A paper, board or plastic roll may appear perfectly fine on the outside. The surface layers may seem to be uniform, smooth, and free of any obvious defects. However, beneath the outer layers, hidden issues can exist that compromise the performance and quality of […]

Hidden roll defects are costing you more than you think

Every mill knows the frustration of a “bad” roll — unscheduled downtime, customer complaints, wasted materials, and production delays. But what if you could detect roll defects before they cause expensive problems? The good news: you can. And it starts with understanding roll hardness profiles.