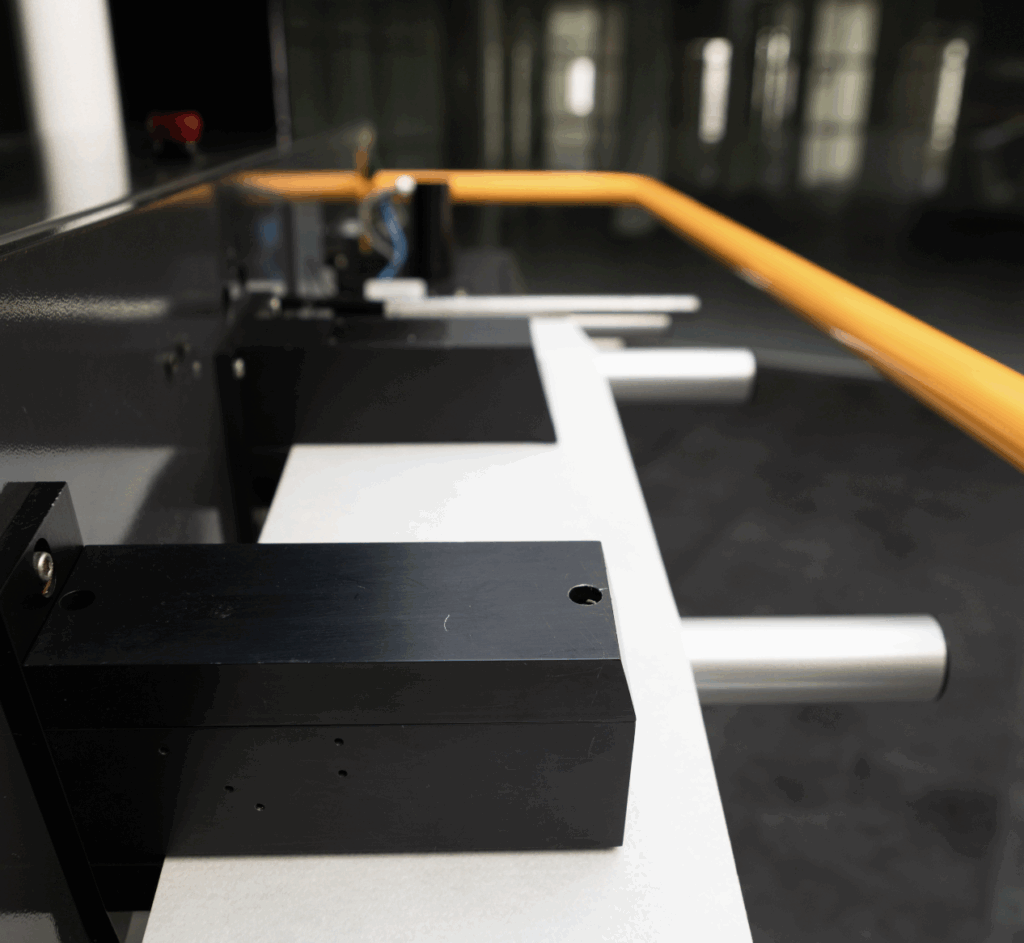

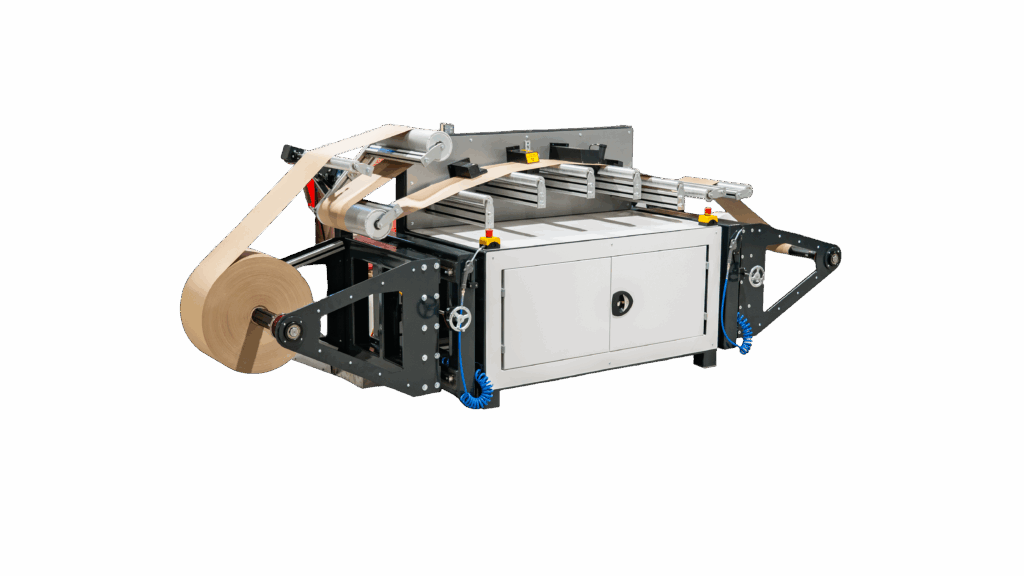

The Tapio Analyzer is an advanced troubleshooting and development system designed for all paper, board, tissue and nonwoven grades. The analyzer measures in laboratory conditions with a controlled web movement, and obtains millimeter-resolution data from several calibrated sensors. By measuring the exact same point in paper with multiple sensors, the analyzer can study the correlation between channels – this further helps to identify the root causes of quality variations, verify and optimize production performance, and ensure measurement accuracy. With analysis tools like spectral analysis, CD profiles, band pass filters, versatile statistics, formation analysis, correlation studies and QCS comparison tools, the system supports both quality control and process development.

Tapio Measurement Technologies offers Tapio Analyzers for high-resolution precision measurement of almost all paper and board grades as well as other suitable rolled products such as tissues and nonwovens.

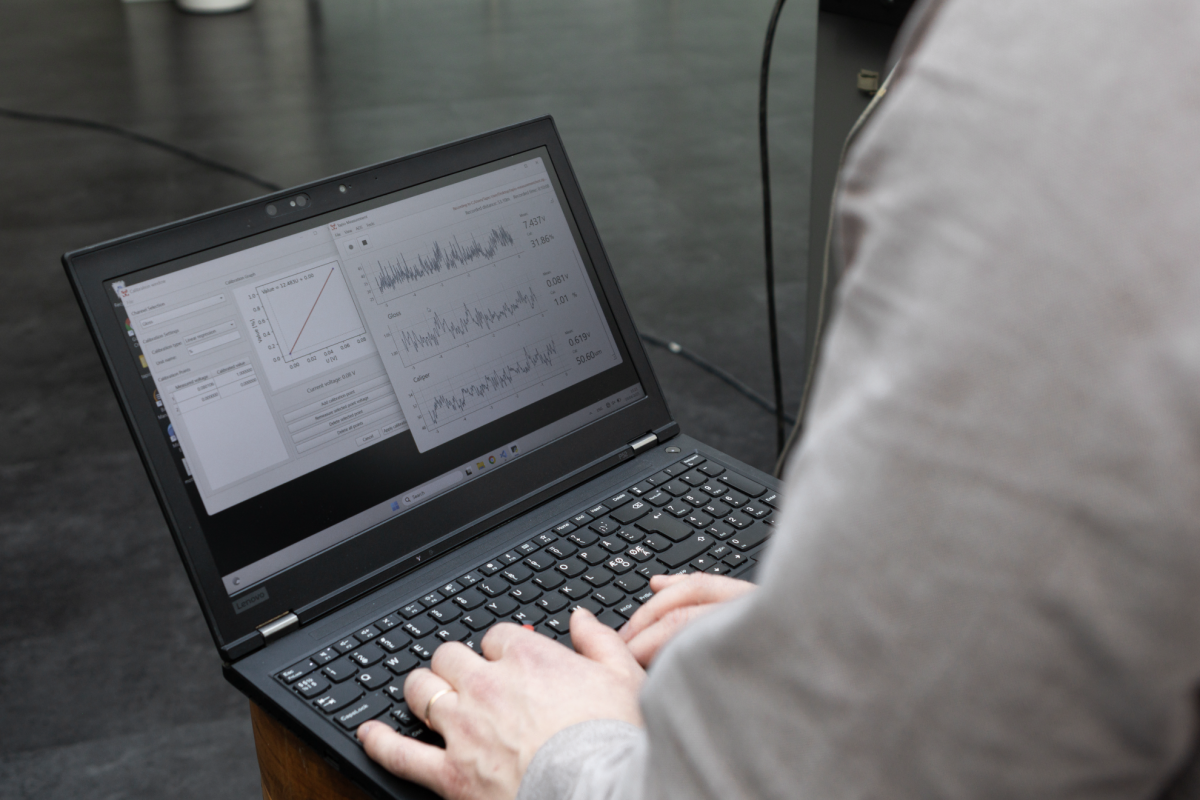

Tapio Analysis is a free and open-source software designed to help paper and board mills improve their quality and solve any production issues.

It can be used for analysis of all Tapio measurement data. The software is approved by all major papermakers and paper machine builders. With advanced tools for CD & MD analysis, it provides unique insight into identifying machine problems and optimizing production processes.

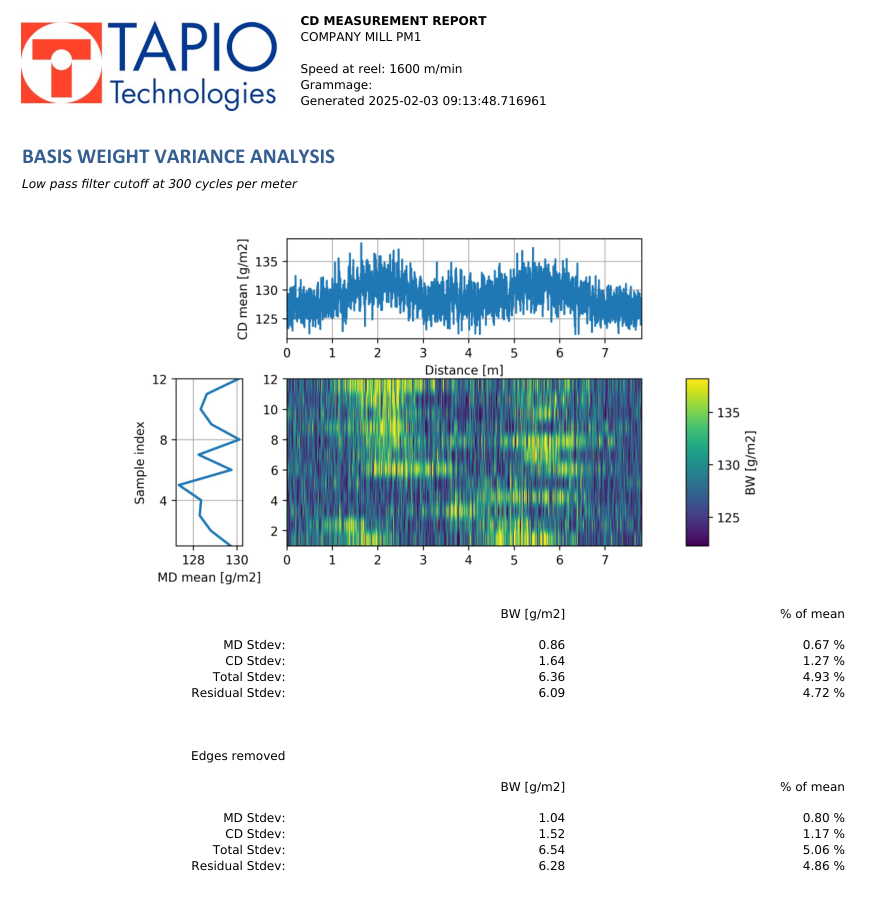

Sometimes measuring or analysis isn’t possible, or you may not be ready to invest in a full Analyzer System. That’s when our measurement, troubleshooting and analysis services are a smart choice.

Send us your samples for analysis! The Tapio Analysis troubleshooting service includes a detailed report on the findings along with a meeting with the Tapio team of experts.